When choosing between vinyl and non-woven materials, you’ll find vinyl offers a smooth, glossy surface with vibrant colors, excellent durability, and resistance to wear, making it perfect for high-traffic areas. Non-woven fabrics are softer, more eco-friendly, and have a natural look, but tend to be less durable and may need replacing sooner. To understand which suits your needs best, explore the material composition, environmental impact, and application options further.

Key Takeaways

- Vinyl offers a glossy, durable surface with vibrant colors, while non-wovens have a softer, matte, fabric-like appearance.

- Vinyl manufacturing involves less eco-friendly processes and is harder to recycle compared to biodegradable, recyclable non-woven fabrics.

- Vinyl is more resistant to abrasion and tearing, making it suitable for high-traffic, long-lasting applications.

- Non-wovens are generally easier to handle during installation and are ideal for eco-conscious, natural, or textured aesthetic uses.

- Vinyl has higher initial costs but offers greater durability, whereas non-wovens tend to be more affordable but with shorter lifespan.

Composition and Manufacturing Processes

Understanding the composition and manufacturing processes of vinyl and non-woven materials is essential to comparing their qualities. Vinyl is made from PVC resin combined with plasticizers, stabilizers, and fillers, then shaped through extrusion or calendaring. Its manufacturing involves applying adhesion techniques to bond layers, enhancing durability. Vinyl’s surface can be coated or printed, affecting adhesion and color retention. Both materials’ manufacturing methods directly impact their performance, with vinyl emphasizing surface treatments for adhesion and colorfastness, while non-wovens focus on fiber bonding techniques for durability. Additionally, product customization options often depend on these manufacturing processes, influencing the final material properties. The bonding methods used in non-wovens also contribute to their breathability and flexibility, making them suitable for a variety of applications. Factors such as material composition play a crucial role in determining the suitability of each material for specific uses, highlighting the importance of manufacturing techniques.

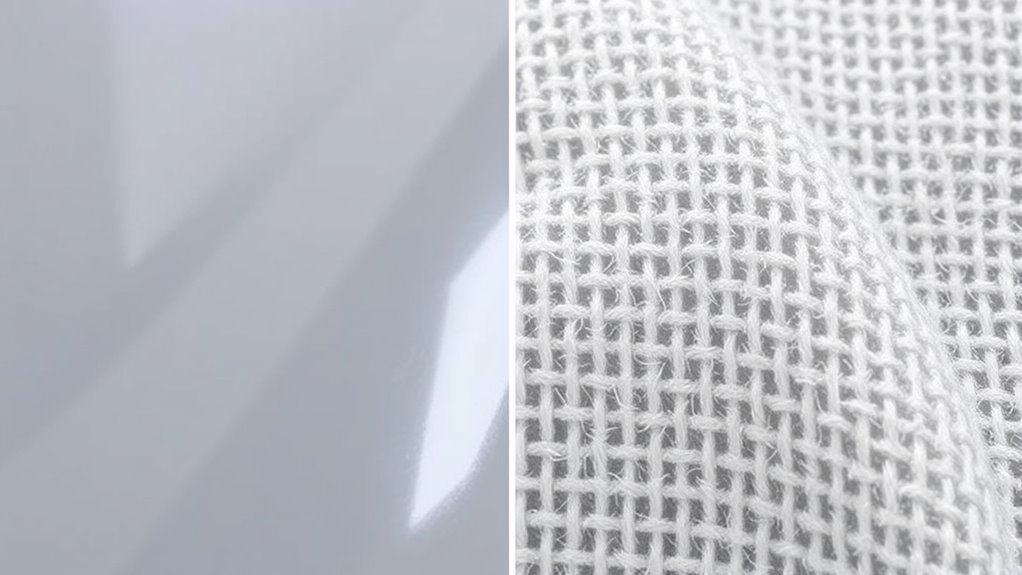

Physical Properties and Appearance

When comparing vinyl and non-woven materials, their physical properties and appearance play a crucial role in determining suitability for various applications. Vinyl offers a smooth, glossy surface with a wide range of texture options, from matte to embossed finishes, giving you flexibility in style. Its color diversity is extensive, allowing for vibrant and consistent hues that resist fading. The durability of vinyl makes it particularly suitable for long-term applications where resistance to wear and environmental factors is important. Non-woven fabrics, on the other hand, tend to have a softer, matte texture that feels more fabric-like and natural. They often feature a more subdued color palette, but can be dyed easily for customization. The visual appeal of vinyl is often more polished and uniform, while non-woven materials provide a more understated, textile-like appearance. Your choice depends on the desired look and tactile experience for your project. Additionally, vinyl’s durability makes it suitable for long-term applications, whereas non-woven fabrics are often chosen for their breathability and eco-friendliness. Understanding the material composition can further help in selecting the right material for specific needs. Moreover, fiber structure influences how each material performs under different conditions, impacting flexibility and maintenance requirements.

Durability and Resistance to Wear

Vinyl generally outperforms non-woven materials in durability and resistance to wear, making it a popular choice for high-traffic applications. Its excellent abrasion resistance helps it withstand frequent foot traffic and friction without showing significant signs of wear. Additionally, vinyl’s superior tear strength ensures it resists ripping or tearing under stress, maintaining its integrity over time. This durability makes vinyl suitable for environments where longevity is essential, such as commercial spaces or busy households. Non-woven materials, while softer and more breathable, typically lack the same level of abrasion resistance and tear strength, which can lead to quicker deterioration in demanding settings. If durability and wear resistance are your top priorities, vinyl provides a more resilient option to meet those needs effectively. Furthermore, high-pressure application capabilities contribute to its robustness, enabling it to maintain performance under demanding conditions and extended use scenarios. The material composition of vinyl also plays a crucial role in its durability, offering additional protection against environmental factors that might degrade other materials faster.

Ease of Installation and Maintenance

Installing vinyl flooring is generally straightforward, thanks to its flexible nature and wide range of adhesive options. You’ll find that its adhesion strength allows for a secure bond, making the installation process smoother and less time-consuming. Vinyl floors typically require minimal preparation, so you can often complete the job quickly. When it comes to maintenance, cleaning frequency is low; regular sweeping and occasional mopping keep vinyl looking fresh. Its smooth surface resists stains and spills, making upkeep simple. Additionally, vinyl’s ease of installation makes it a popular choice for DIY projects. Its durability and waterproof qualities also contribute to its long-term performance, reducing the need for frequent repairs. Non-woven materials, on the other hand, might need more careful handling during installation due to their less flexible nature. Overall, vinyl flooring offers an easier installation process and easier maintenance, saving you time and effort in the long run.

Environmental Impact and Sustainability

When considering environmental impact, you should look at how each material is produced and whether it’s recyclable to reduce waste. Vinyl often involves less eco-friendly manufacturing, while non-woven options can be more sustainable if properly recycled. Think about the long-term effects on the environment as you choose between these materials. Additionally, embracing mindful decluttering strategies can help reduce unnecessary consumption and waste associated with these materials. Exploring sustainable material choices can further enhance your efforts toward eco-conscious home decor. Being aware of manufacturing processes can also inform your decisions regarding environmental impact and sustainability. Recognizing the recyclability potential of these materials is crucial for making environmentally responsible choices.

Eco-Friendly Production Methods

While both vinyl and non-woven materials have environmental impacts, non-woven options generally promote more sustainable production methods. Non-woven fabrics often use renewable resource sourcing, such as plant-based fibers, reducing reliance on fossil fuels. This approach minimizes environmental harm and supports eco-friendly manufacturing. Additionally, biodegradability concerns influence material choices; many non-woven options are designed to break down more easily in natural environments, lessening long-term waste. Environmental Impact Furthermore, non-woven materials often involve safer chemical processes, contributing to their overall sustainability profile. Embracing sustainable manufacturing practices can significantly reduce ecological footprints. Vinyl production, on the other hand, involves chemicals and processes that are less sustainable and contribute to pollution. By choosing non-woven materials, you support production methods that prioritize renewable resources and reduce environmental footprints, making them a more eco-conscious choice for sustainable manufacturing.

Recyclability and Waste

Recyclability and waste are critical factors to contemplate when choosing between vinyl and non-woven materials. Vinyl is generally less recyclable due to its plastic composition, often ending up in landfills despite some recycling programs attempting to manage it. Non-woven fabrics, especially those made from polypropylene, are more amenable to recycling and waste reduction efforts. They can often be repurposed or processed into new products, reducing environmental impact. Your choice can influence waste generation; opting for recyclable materials helps minimize landfill accumulation. Supporting products that participate in recycling programs not only promotes sustainability but also encourages manufacturers to develop eco-friendlier practices. Additionally, understanding the environmental impact of each material can guide more responsible purchasing decisions. For instance, choosing recyclable non-woven fabrics over vinyl can significantly reduce plastic waste and pollution. Moreover, the development of recycling technologies continues to improve the efficiency and scope of material recovery processes, further supporting sustainable choices. Furthermore, considering the recyclability of materials can help consumers make more sustainable choices that align with global efforts to reduce waste and promote circular economies. In the end, considering recyclability and waste management options guarantees your decision aligns with environmental preservation goals.

Long-Term Environmental Effects

Choosing between vinyl and non-woven materials considerably impacts their long-term environmental effects. Vinyl poses recycling challenges due to its complex composition, making it difficult to process and often leading to waste that persists in landfills. Its durability means it lasts longer but also contributes to environmental pollution if not properly disposed of. Non-woven fabrics typically have fewer recycling issues, but their biodegradability concerns vary depending on the materials used. Some non-wovens decompose more readily, reducing long-term waste, while others may take years to break down. Your choice influences sustainability, as materials with better biodegradability reduce environmental footprint, whereas those with recycling challenges may accumulate and cause pollution over time. Consider these factors carefully to minimize long-term environmental impact, and material properties play a crucial role in determining overall environmental sustainability.

Common Applications and Use Cases

Vinyl and non-woven materials find their way into many everyday items, from wall coverings and decor to packaging solutions. You’ll notice them in apparel and fashion items, where durability and appearance matter. Understanding these common applications helps you choose the right material for your specific needs.

Wall Coverings and Decor

Wall coverings and decor are popular ways to transform living and commercial spaces, adding personality, texture, and style. With a wide range of pattern options, you can easily find designs that suit any aesthetic, from bold geometric shapes to subtle textures. The color variety also allows you to match or contrast with your existing decor, creating visual interest or a calming atmosphere. Vinyl is known for its vibrant, long-lasting prints, making it ideal for accent walls or feature areas. Non-woven materials often offer more subtle, matte finishes, perfect for creating a sophisticated look. Whether you prefer the durability and versatility of vinyl or the eco-friendly, breathable qualities of non-woven, both materials provide excellent solutions for enhancing your walls with style and character.

Packaging and Wrapping Solutions

Packaging and wrapping solutions are essential across various industries for protecting, presenting, and branding products. Vinyl and non-woven materials offer unique advantages, especially in design versatility and aesthetic appeal. Vinyl wraps provide a glossy, durable finish that enhances product visibility and attracts attention. They’re ideal for high-end packaging or promotional displays that demand a sleek look. Non-woven fabrics, on the other hand, excel in eco-friendly packaging, offering a soft, flexible surface with a natural aesthetic appeal. They’re perfect for gift wrapping, retail bags, and branding that emphasizes sustainability. Both materials can be customized with printing, colors, and textures, allowing you to craft solutions tailored to your brand’s image. Whether you seek durability or eco-consciousness, these options serve a wide range of packaging and wrapping needs.

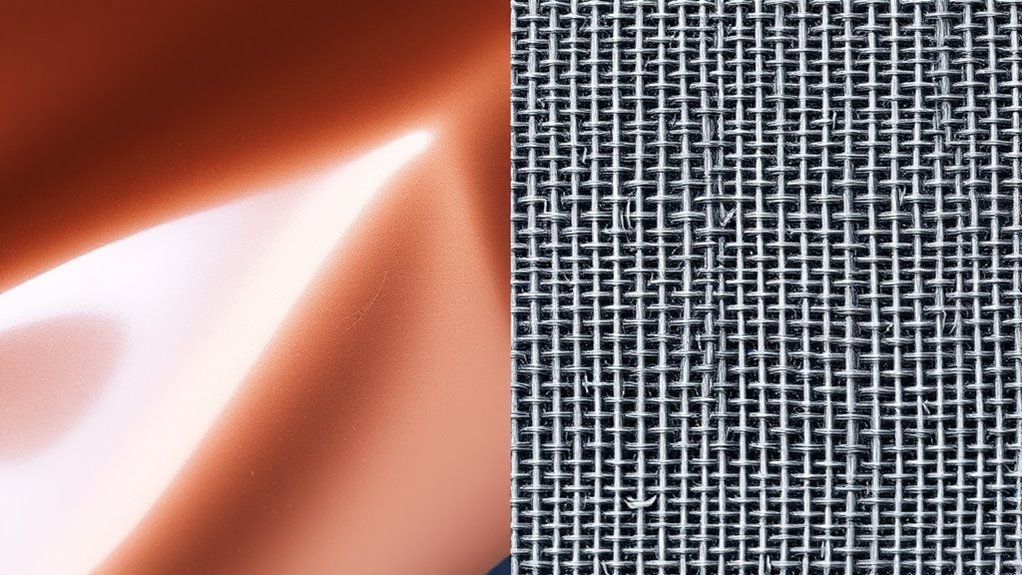

Apparel and Fashion Items

When it comes to apparel and fashion items, choosing the right material can make a significant difference in presentation and durability. Vinyl offers a sleek, glossy finish with a smooth texture, providing a modern look, while non-woven fabrics bring a softer, matte feel that’s comfortable against the skin. Both materials offer diverse texture options, allowing you to select finishes that match your design vision. Color diversity is another advantage: vinyl easily holds vibrant, long-lasting hues, making it ideal for bold fashion statements. Non-woven fabrics, on the other hand, often feature more subdued tones but can be dyed or printed to achieve a wide range of colors. Your choice depends on whether you prioritize a high-gloss aesthetic or a softer, more breathable feel.

Cost Considerations and Value

While vinyl often has a higher upfront cost, it can offer better long-term value due to its durability and low maintenance needs. This makes it a smart choice if you’re contemplating pricing strategies that maximize longevity and reduce replacement costs. Vinyl’s resilience means fewer repairs and replacements over time, saving you money in the long run. Additionally, its surface offers excellent branding opportunities, allowing you to incorporate detailed logos or vibrant designs without worry. Non-woven materials typically cost less initially but may require more frequent replacement, which can add up over time. When evaluating value, consider how durability and branding potential can offset initial expenses. By weighing these factors, you can make a more informed decision that aligns with your budget and branding goals.

Frequently Asked Questions

How Do Vinyl and Non-Woven Materials Compare in Sound Insulation?

Vinyl typically offers better sound absorption than non-woven materials, making it a good choice for noise reduction. It also provides a durable, seamless surface that enhances insulation. Non-woven materials may be easier to install and handle but usually don’t match vinyl’s soundproofing qualities. Your decision should consider how important sound insulation is versus installation ease, balancing long-term comfort with practicality.

Which Material Is Better Suited for High-Traffic Commercial Spaces?

For high-traffic commercial spaces, vinyl is the better choice due to its superior durability and resistance to wear and tear. You’ll appreciate its longevity and ease of maintenance, which keep it looking good longer. Plus, vinyl offers excellent aesthetic versatility, allowing you to choose from a wide range of styles and finishes to match your décor. It’s designed to withstand constant foot traffic without degrading, making it ideal for busy environments.

Are There Health Concerns Associated With Vinyl or Non-Woven Fabrics?

You should be aware that vinyl can emit indoor emissions due to chemicals used in manufacturing, raising concerns about chemical safety. Non-woven fabrics generally have lower emissions and are considered safer for indoor air quality. If chemical safety is a priority, choose non-woven materials, especially in spaces with sensitive occupants. Always check product certifications to verify they meet health standards and minimize potential health risks.

How Do Vinyl and Non-Woven Materials Perform in Extreme Weather Conditions?

Vinyl and non-woven materials handle extreme weather differently. Vinyl offers excellent UV resistance, so it won’t fade or crack easily under intense sunlight, and it’s fire-safe, reducing risk in heat. Non-woven fabrics may struggle with UV exposure, leading to deterioration over time, and generally aren’t as fire-safe. For durability in harsh conditions, vinyl is your best choice, providing reliable performance and safety.

Can Vinyl or Non-Woven Fabrics Be Recycled Easily?

You can recycle vinyl and non-woven fabrics, but recycling challenges exist. Vinyl often contains plasticizers, making it harder to process and recycle efficiently, which impacts its environmental footprint. Non-woven fabrics, especially if made from synthetic fibers, may also pose recycling difficulties due to contaminants or bonding agents. Both materials have environmental impacts during disposal, so consider eco-friendly options and proper recycling methods to reduce waste and support sustainability efforts.

Conclusion

Choosing between vinyl and non-woven materials depends on your needs. Vinyl offers durability and water resistance, while non-woven options excel in breathability and eco-friendliness. Did you know that over 80% of homeowners prefer eco-conscious choices? By understanding each material’s strengths, you can make a confident decision that suits your lifestyle and values. Ultimately, selecting the right material guarantees lasting satisfaction and a positive impact on the environment.